Introduction

The industrial automation software market is rapidly becoming one of the most transformative forces in the global manufacturing sector. With rising demand for efficiency, scalability, and cost optimization, industries across the board—from automotive to pharmaceuticals—are embracing automation at an unprecedented rate.

Industrial automation software plays a crucial role in this shift by enabling machines and systems to operate with minimal human intervention while maintaining high levels of precision, consistency, and reliability.

The market has evolved significantly over the last decade, moving from simple programmable logic controllers (PLCs) to advanced software suites that include artificial intelligence, machine learning, predictive maintenance, and real-time data analytics. As we move deeper into the era of Industry 4.0, the growth trajectory of the industrial automation software market shows no signs of slowing down.

Evolution And Historical Context

To fully understand the present state of the industrial automation software market, it is important to look at its evolution. Automation in industry began with the mechanization of simple tasks, which over time evolved into the integration of electronics and information technology. The introduction of PLCs in the late 20th century revolutionized factory operations, enabling automated control of manufacturing processes.

As computing power increased and internet connectivity became widespread, the scope of automation expanded to include complex software solutions capable of controlling entire production lines. In recent years, the rise of digital transformation has propelled automation software into a central role in enterprise operations.

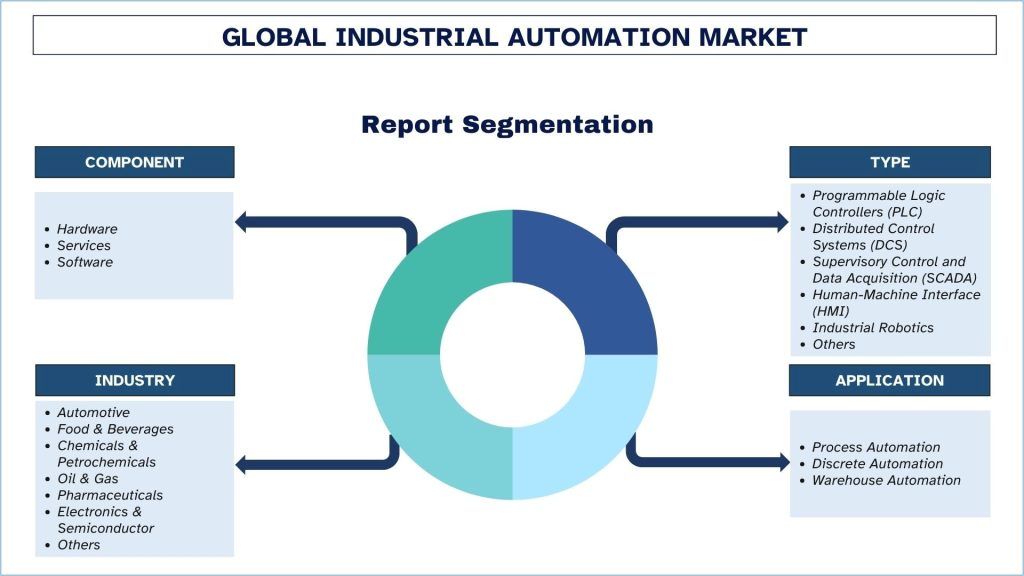

The market now includes various software categories such as Human-Machine Interface (HMI), Manufacturing Execution Systems (MES), Supervisory Control and Data Acquisition (SCADA), and industrial Internet of Things (IIoT) platforms.

Market Dynamics And Growth Drivers

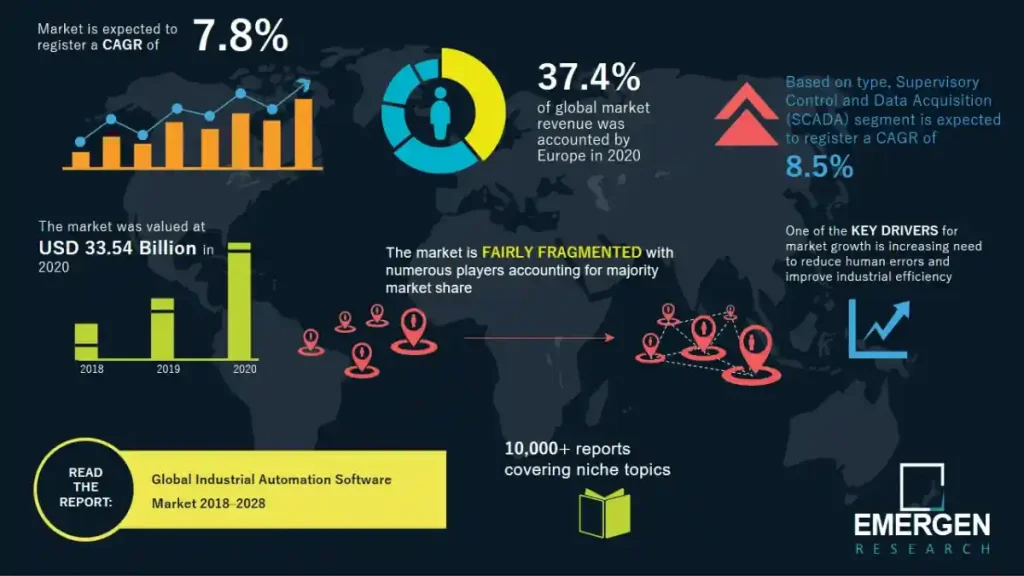

The rapid growth of the industrial automation software market can be attributed to several key factors. One major driver is the increasing demand for productivity and efficiency in manufacturing operations. Companies are under constant pressure to reduce operational costs while improving output quality, and automation software provides the tools to achieve these goals.

Another critical factor is the global labor shortage in skilled manufacturing roles. As experienced technicians retire and fewer young professionals enter the field, automation becomes a necessary solution to maintain production levels.

The growing focus on digital transformation and smart factories is also pushing businesses to invest in advanced automation software. In addition, governmental regulations and environmental concerns are driving the adoption of solutions that minimize waste, optimize energy use, and reduce carbon footprints. These combined factors are expected to sustain market growth well into the foreseeable future.

Key Software Segments In Industrial Automation

The industrial automation software market comprises several important software types, each serving a specific function in the automation ecosystem. One of the foundational elements is the Manufacturing Execution System (MES), which bridges the gap between enterprise resource planning (ERP) and plant-floor operations.

MES software enables real-time monitoring and control of production processes, ensuring that every stage of manufacturing adheres to defined quality standards. SCADA systems, on the other hand, are essential for real-time data acquisition and control of industrial processes across large geographical areas.

Human-Machine Interface (HMI) software allows operators to interact with machinery through graphical displays and control panels, improving usability and responsiveness. Another growing segment is Product Lifecycle Management (PLM) software, which integrates data, processes, and business systems to manage product information throughout its life cycle.

As artificial intelligence and machine learning continue to make their way into industrial environments, predictive analytics and automated decision-making are becoming integral components of the software stack.

Industry 4.0 And Smart Manufacturing

The concept of Industry 4.0 represents a new phase in the Industrial Revolution, characterized by the integration of cyber-physical systems, the Internet of Things, and cloud computing. At the heart of this transformation is industrial automation software, which acts as the digital backbone of smart factories. These factories leverage interconnected systems to automate decision-making, enhance operational visibility, and reduce downtime through predictive maintenance. Industrial automation software enables seamless communication between machines, sensors, and central control systems, ensuring that production is adaptive and responsive.

This digital interconnectivity empowers manufacturers to implement just-in-time production, reduce inventory costs, and meet fluctuating customer demands more efficiently. By enabling the automation of both physical and digital processes, Industry 4.0 is making it possible for manufacturers to achieve unprecedented levels of agility and scalability.

Role Of Artificial Intelligence And Machine Learning

Artificial intelligence and machine learning are playing an increasingly critical role in the evolution of industrial automation software. These technologies enable software systems to learn from data, recognize patterns, and make decisions with minimal human input. In manufacturing environments, AI-powered analytics can predict equipment failures before they occur, recommend optimal production schedules, and identify inefficiencies in the workflow.

Machine learning algorithms can also help in quality control by detecting anomalies that may not be visible to the human eye or traditional sensors. The integration of AI into industrial automation software not only enhances operational efficiency but also contributes to a culture of continuous improvement. As more data becomes available through sensors and connected devices, the ability of AI to generate actionable insights will continue to drive innovation in the industrial automation software market.

Regional Trends And Market Penetration

The industrial automation software market exhibits distinct regional trends based on local economic development, industrial infrastructure, and government policy. North America, particularly the United States, has been a leader in adopting advanced automation solutions, driven by the need to revitalize its manufacturing base and improve competitiveness. Europe, with its strong emphasis on sustainability and innovation, has also seen rapid adoption, especially in countries like Germany, which spearheaded the Industry 4.0 initiative.

In Asia-Pacific, countries such as China, Japan, and South Korea are investing heavily in automation to support massive manufacturing sectors and overcome rising labor costs. Emerging markets in Latin America, the Middle East, and Africa are beginning to explore automation as they develop their industrial capabilities and seek to attract foreign investment. These regional differences influence the types of automation solutions deployed and the pace at which digital transformation occurs, contributing to a highly dynamic and fragmented global market.

Challenges In Implementation

Despite its advantages, implementing industrial automation software comes with a unique set of challenges. One of the most significant hurdles is the high initial investment required, which can be prohibitive for small and medium-sized enterprises. In addition, integrating automation software with legacy systems and existing hardware often requires specialized expertise and careful planning.

Cybersecurity is another growing concern, especially as factories become more connected and reliant on cloud-based solutions. Ensuring data privacy and protecting systems from cyber threats requires ongoing investment in security protocols and employee training. Resistance to change is also a common barrier, as operators and managers may be hesitant to adopt new technologies that disrupt traditional workflows. Overcoming these challenges requires a clear strategy, stakeholder buy-in, and a willingness to invest in long-term gains over short-term convenience.

Competitive Landscape And Major Players

The industrial automation software market is highly competitive, with a mix of established players and emerging startups vying for market share. Global giants such as Siemens, Rockwell Automation, ABB, Schneider Electric, and Honeywell offer comprehensive automation solutions that integrate hardware, software, and services. These companies have decades of experience and a global footprint, making them preferred partners for large-scale industrial projects.

At the same time, new entrants and specialized software vendors are gaining traction by offering innovative, cloud-native, and AI-driven solutions that address specific industry needs.

Companies like PTC, AspenTech, GE Digital, and AVEVA are introducing cutting-edge technologies that allow for greater customization, scalability, and integration.

This competitive environment is driving rapid innovation and pushing vendors to differentiate themselves through enhanced functionality, customer support, and value-added services.

Impact Of Covid-19 And Post-Pandemic Outlook

The COVID-19 pandemic had a profound impact on manufacturing and supply chain operations worldwide, highlighting the vulnerabilities of manual and labor-intensive processes.

In response, many companies accelerated their adoption of industrial automation software to maintain continuity, manage remote operations, and reduce human dependency.

Remote monitoring, digital twins, and cloud-based SCADA systems became essential tools during lockdowns and restricted access to facilities. The pandemic served as a catalyst for digital transformation, prompting businesses to re-evaluate their technology strategies and invest in more resilient and adaptable systems.

As the world recovers, the demand for flexible, scalable, and intelligent automation solutions is expected to grow, with a greater emphasis on building smart factories that can withstand future disruptions.

Future Trends And Market Outlook

The future of the industrial automation software market is shaped by continuous technological innovation, evolving customer expectations, and changing economic conditions. Edge computing is gaining momentum, allowing for real-time processing of data closer to the source, which reduces latency and enhances responsiveness. The convergence of IT and OT (Operational Technology) is also creating new opportunities for seamless data exchange and unified control systems.

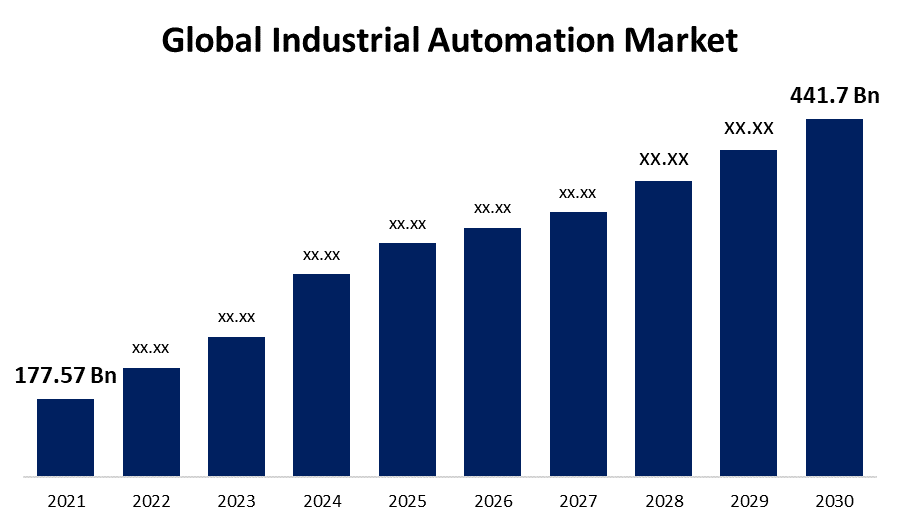

Sustainability will continue to be a major focus, with software solutions playing a key role in optimizing energy usage and minimizing waste. Cloud-based platforms are expected to dominate, providing greater scalability, accessibility, and cost-effectiveness.

As automation becomes more intelligent and autonomous, the lines between software, hardware, and human roles will continue to blur. The industrial automation software market is poised for sustained growth, driven by innovation, necessity, and the unrelenting pursuit of operational excellence.

Conclusion

The industrial automation software market is at the forefront of a technological revolution that is redefining how industries operate, compete, and grow. From enhancing production efficiency and enabling predictive maintenance to fostering smart manufacturing and supporting sustainability, automation software is a critical enabler of modern industry. Its applications are diverse, spanning across manufacturing, energy, transportation, and logistics, with each sector reaping unique benefits.

The integration of AI, IoT, and cloud technologies has elevated the capabilities of industrial automation software, making it smarter, more adaptive, and increasingly central to strategic decision-making. While challenges remain in terms of cost, integration, and security, the long-term advantages far outweigh the hurdles.

As industries continue to digitize and innovate, the demand for robust, flexible, and intelligent automation solutions will only grow. In this evolving landscape, businesses that embrace automation and invest in future-ready software platforms will be best positioned to thrive in the next industrial era.